Find the newest trends and common knowledge in lenticular printing business.

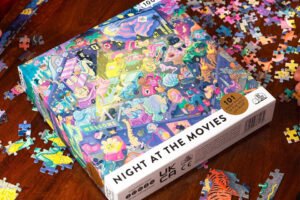

Unlocking the Magic of Lenticular Puzzles: Where Art Meets Illusion

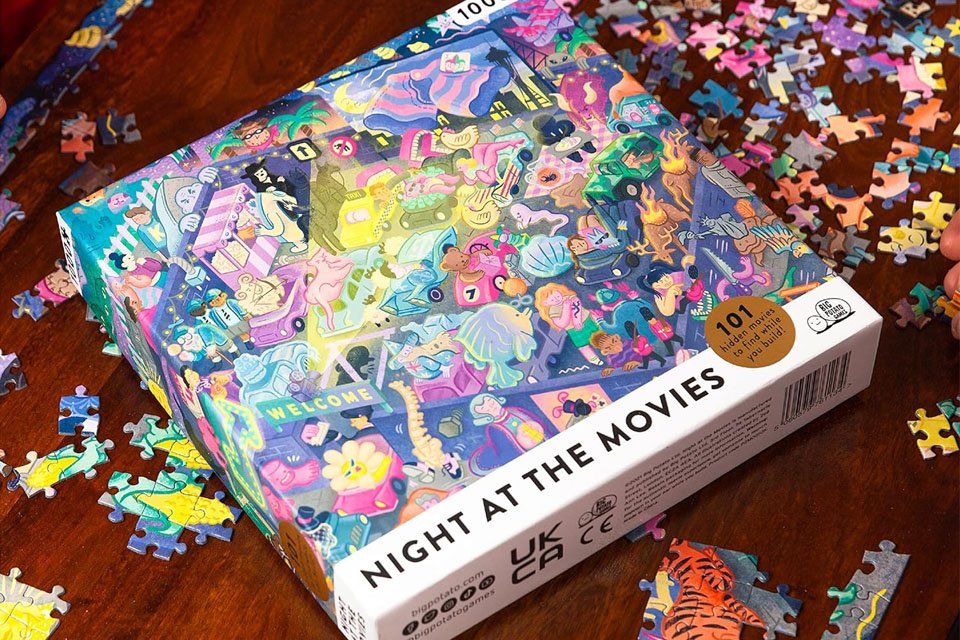

Step into a world where puzzles come alive and images transform before your eyes! Welcome to the fascinating realm of lenticular puzzles, where traditional jigsaw challenges meet cutting-edge optical illusions.

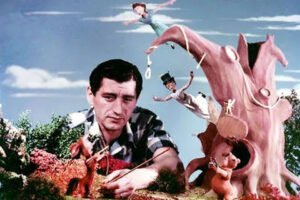

Unlocking the Magic of 3D Lenticular Prints: A Visual Revolution

Are you ready to step into a world where images come alive, leap off the page, and captivate your senses?

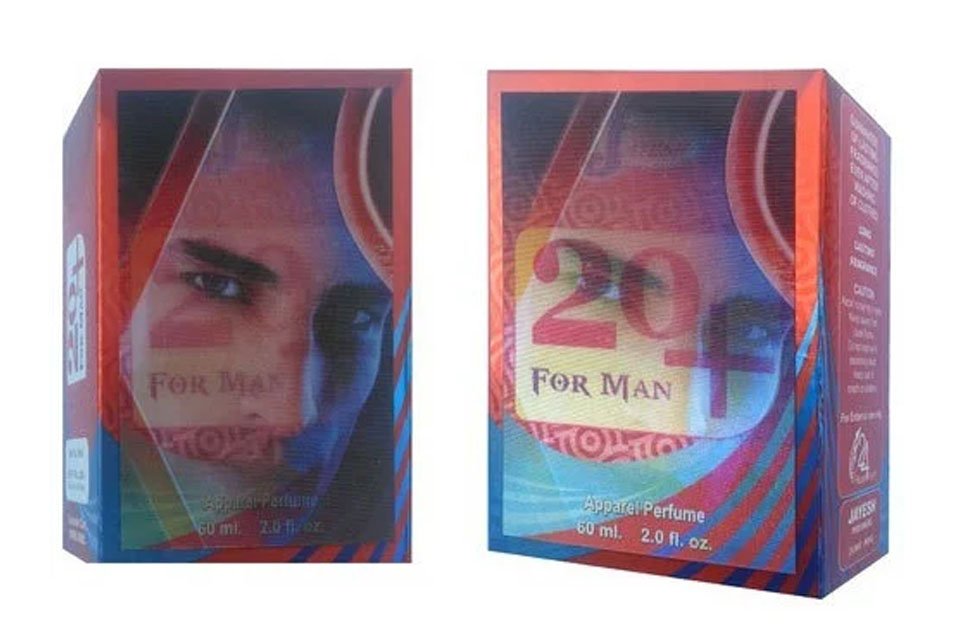

Revolutionize Your Brand with 3D Lenticular Printing Packaging

Step into the future of packaging design with 3D lenticular printing! This cutting-edge technology is transforming the way products are presented, creating eye-catching, interactive experiences that captivate consumers.